How To Fix A Varnish Spot On Furniture

From scratches to discoloration, the surfaces of your wooden furniture are vulnerable to all kinds of harm. Luckily, many of the problems tin be fixed.

In this article, we'll tell y'all how. You'll learn how to repair everything from gouges to burns. You'll even find tips for repairing article of furniture veneer and hardware. We'll start by discussing surface stains and discoloration.

Removing Stains and Discoloration

Most finishes protect the surface of wooden piece of furniture past forming a protective coating. To repair a damaged finish blanket, work only to the depth that it's affected. On any surface, work carefully, and don't remove more of the terminate than you accept to. In this article, nosotros'll discuss this and other simple techniques to help you lot remove stains, blushing, and other discoloration from the surfaces of wooden piece of furniture.

White spots: Shellac and lacquer finishes are not resistant to water and alcohol. Spills and condensation from glasses can leave permanent white spots or rings on these finishes. To remove these white spots, showtime try polishing the surface with liquid furniture smoothen; buff the surface firmly. If this doesn't piece of work, lightly wipe the stained surface with denatured alcohol. Use equally little booze every bit possible; likewise much volition damage the cease.

If neither polishing nor alcohol handling removes the white spots, the damaged stop must be treated with abrasives. Gentle abrasives tin be purchased from a home-supply store. To make your own gentle annoying, mix cigarette ashes to a paste with a few drops of vegetable oil, light mineral oil, or linseed oil. Rub the ash-oil paste over the stained area, along the grain of the wood, then wipe the surface clean with a soft textile. If necessary, repeat the procedure. Stubborn spots may require several applications. Then wax and smoothen the entire surface.

If rubbing with ashes is not effective, go over the stained area with a mixture of rottenstone and linseed oil. Mix the rottenstone and oil to a thin paste, and rub the paste gently over the stain, along the grain of the wood. Rottenstone is a fast-cutting abrasive, and so rub very carefully. Bank check the surface frequently to brand sure you aren't cutting as well deep. As shortly as the white spots disappear, stop rubbing and wipe the woods clean with a soft textile. Then apply two coats of hard furniture wax and vitrify the woods to a shine.

Blushing: Blushing, a white brume over a large surface or an unabridged furniture, is a mutual problem with sometime shellac and lacquer finishes. The discoloration is acquired by moisture, and it tin can sometimes exist removed the same way white spots are removed. Buff the surface lightly and evenly with No. 0000 steel wool dipped in linseed oil. Work with the grain of the woods, rubbing evenly on the unabridged surface, until the white haze disappears. Then wipe the woods make clean with a soft material, apply two coats of difficult furniture wax, and buff the surface to a smoothen.

Blushing can sometimes be removed past reamalgamation. If the surface is crazed or alligatored, reamalgamation should exist used instead of steel-wool rubbing. If neither rubbing nor reamalgamation removes the brume, the piece of furniture must exist refinished.

Black spots: Blackness spots are caused past h2o that has penetrated the stop completely and entered the woods. They cannot be removed without damage to the finish. If the spots are on a conspicuously defined surface, you may be able to remove the finish from this surface just; otherwise, the entire slice of article of furniture will have to be stripped. When the finish has been removed, bleach the entire stained surface with a solution of oxalic acrid. And then refinish equally necessary.

Ink stains: Ink stains that have penetrated the finish, like blackness water spots, cannot be removed without re-finishing. Less serious ink stains can sometimes be removed. Lightly buff the stained area with a textile moistened with mineral spirits; then rinse the wood with clean water on a soft textile. Dry out the surface thoroughly, and and then wax and polish it.

If this does not remove the ink, lightly rub the stained area, along the grain of the forest, with No. 0000 steel wool moistened with mineral spirits. Then wipe the surface clean and wax and polish it. This treatment may harm the finish. If necessary, refinish the damaged spot as discussed below. If the area is badly damaged, the entire surface or piece of furniture will take to be refinished.

Grease, tar, pigment, crayon, and lipstick spots: These spots normally affect only the surface of the end. To remove wet paint, use the appropriate solvent on a soft cloth -- mineral spirits for oil-base pigment, water for latex paint. To remove dry out paint or other materials, very carefully lift the surface balance with the edge of a putty knife. Do not scrape the wood, or yous'll scratch the terminate. When the surface fabric has been removed, buff the area very lightly along the grain of the woods with No. 0000 steel wool moistened with mineral spirits. And so wax and smooth the entire surface.

Wax and gum spots: Wax and gum usually come off easily, just they must exist removed carefully to prevent impairment to the finish. To make the wax or gum brittle, press it with a package of ice wrapped in a towel or newspaper towel. Let the deposit harden; then lift it off with your thumbnail. The hardened wax or gum should popular off the surface with very fiddling pressure. If necessary, repeat the ice awarding. Do non scrape the deposit off, or you'll scratch the end.

When the wax or mucilage is completely removed, buff the area very lightly along the grain of the forest with No. 0000 steel wool moistened with mineral spirits. Then wax and polish the entire surface.

Spot Refinishing

Any repair that involves removing the damaged finish completely -- deep scratches, gouges, burns, or whatsoever other impairment -- likewise involves refinishing the repair area. Spot refinishing is not always piece of cake, and it'southward not always successful, peculiarly on stained surfaces. If the damage isn't also bad, it'due south worth trying. If you'll have to touch upwardly several areas on one surface, you lot're probably meliorate off refinishing the surface or the furniture completely.

To stain one area on a surface, use an oil-based stain that matches the surrounding stain. You lot may have to mix stains to get a expert friction match. Examination the stain on an inconspicuous unfinished part of the forest before working on the finished surface.

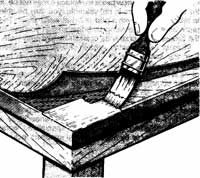

Before applying the stain, prepare the damaged area for finishing. Sealing is not necessary. Utilise the stain to the damaged area with an artists' brush or a clean cloth, covering the entire bare area. Permit the stain set for 15 minutes and and then wipe it off with a clean material. If the colour is also light, apply another coat of stain, look 15 minutes, and wipe once more. Repeat this procedure until y'all're satisfied with the color; then let the stain dry according to the manufacturer's instructions.

Lightly buff the stained surface with No. 0000 steel wool, and wipe information technology clean with a tack cloth. Use a new coat of the same finish already on the surface -- varnish, penetrating resin, shellac, or lacquer -- over the newly stained surface area, feathering out the new finish into the surrounding one-time finish. Permit the new finish dry for one to 2 days, and lightly buff the patched area with No. 0000 steel wool. Wax the unabridged surface with hard paste wax, and polish it to a smooth.

Read the next page to find what to do if your furniture has scratches, dings, or dents.

How to Repair Scratches, Dings, and Dents

Old or new, wooden furniture often shows signs of all-encompassing utilize: scratches, dings, and dents. Well-nigh of these surface amercement are easy to repair, unless the problem is severe and all-encompassing.

Scratches

To hide small scratches quickly, interruption the meat of a walnut, pecan, or Brazil nut and rub it along the scratch. The oil in the nut meat volition darken the raw scratch.

Where many shallow scratches are present, apply hard paste wax to the surface with No. 0000 steel wool, stroking very lightly along the grain of the wood. So buff the surface with a soft material. For shallow scratches on an otherwise sound shellac or lacquer finish, reamalgamation can be used to restore the finish.

For one or two deeper scratches, article of furniture-patching wax sticks are usually effective. These retouching sticks, made

in several forest colors, are bachelor at hardware and sometimes grocery stores. Cull a stick to match the finish. To use the wax stick, run it firmly along the scratch, applying enough pressure to make full the scratch with wax. Remove any excess wax with the border of a credit carte du jour or other thin plastic card. Let the wax dry; so buff with a soft textile.

Badly scratched surfaces should usually be re-finished, but to hide ane or ii very deep scratches, you may be able to stain the raw surface area to friction match. Utilize oil-based stain with an artists' brush, drawing it carefully along the scratch; let it represent 15 minutes and wipe information technology off. If necessary, repeat this procedure until the scratch matches the rest of the wood.

Let the surface area dry completely, as directed past the stain manufacturer. Then employ hard paste wax and buff the waxed surface to a shine.

Dings

Dings are tiny chips in the stop, unremarkably caused past a sharp accident. The wood may not be afflicted. To repair a ding, utilize a sharp craft pocketknife to remove whatever loose finish in or effectually the ding. Work carefully, scraping the damaged spot with the flat, abrupt edge of the knife blade; do not scratch the spot. Then very advisedly feather the edges of the ding with No. 0000 steel wool.

Clean the ding area with a soft cloth moistened in mineral spirits, and let it dry completely. Then, with an artists' brush, carefully apply new finish to the spot -- varnish, shellac, lacquer, or enamel -- to match the rest of the terminate. The spot will be very noticeable at first. Permit the stop dry out; it will exist glossy. So lightly buff the spot with No. 0000 steel wool, and wax and shine the entire furniture. The ding should blend perfectly when the job is complete.

Dents

Small, shallow dents in pino and other soft woods are ordinarily easy to remove; big and deep dents, especially in hard forest, are harder to repair. Dents are easiest to remove from bare wood. Very large, shallow dents are probably best left untreated. Very deep dents should exist filled, as detailed below for cracks and gouges.

© Publications International, Ltd. Use a fine pin or needle to drive a serial of minor holes in a stubborn dent; then swell the woods to enhance the dent.

On finished surfaces, yous'll have to remove the finish around the damaged area. Using fine-grit sandpaper, carefully remove the terminate for about 1/2 inch around the spot. To raise the wood in the dent, apply a few drops of water to the dent and let the water penetrate the wood for a day or so. Do not moisture the entire surface. This treatment may be enough to enhance the dent, especially if the paring is shallow and the wood is soft.

If this doesn't raise the dent, soak a cloth in water and wring it out. Place the clammy material, folded in several layers, over the dent; then press the cloth firmly with a warm iron.

Exist careful not to touch the iron directly to the wood. This moist heat may be enough to swell the wood and heighten the dent. If it isn't, apply a commercial wood-swelling liquid to the surface area and give it time to work -- about a day or so, equally directed by the manufacturer.

For deep dents that can't be raised with water, heat, or wood sweller, use a fine direct pin or needle to drive a series of holes in the dent. Pound the straight pin in about i/4 inch, and advisedly pull it out with pliers; the holes should be as pocket-size as possible. Then treat the dent you would for a shallow paring. The pinholes let the water penetrate the wood's surface. If you lot're careful, the holes won't evidence when the wood has been raised.

After the dent has been raised, permit the wood dry for well-nigh a week, and and then refinish the damaged area as above. Let the finish dry out completely. Lightly buff the new finish with No. 0000 steel wool, and and so wax and polish the entire surface.

Deeper cracks and gouges in the surface may require additional piece of work. Learn the basic steps to repair cracks and gouges on wooden furniture in the next section.

How to Repair Cracks and Gouges

Cracks and gouges are a common problem on wooden furniture, peculiarly if the slice is sometime or is excessively used. Some basic restoration techniques can remove these problems equally long every bit the harm hasn't gone across the surface.

Cracks and gouges should be filled so that they're level with the surface of the wood. For very pocket-size holes, similar staple holes, woods-tone putty sticks can exist used. If you tin can't match the wood, several colors tin can be mixed together. To use a putty stick, wipe information technology across the pigsty and polish the surface with your finger. If yous plan to terminate or refinish the forest, permit the putty dry out for at least a week before proceeding further.

For larger holes, wood filler and water putty are the easiest fillers. These fillers can be used on blank or finished wood. Wood filler is available in several colors, and water putty can exist tinted with oil or h2o stain. Withal, forest filler and water putty patches are commonly noticeable, and may expect darker than the wood. For the best results, examination the patch on an inconspicuous surface to make certain the color is right.

To use forest filler, carefully make clean the crack or gouge with the tip of a craft knife, and then press the plastic firmly in with the tip of a craft knife or the border of a putty knife. Wood filler shrinks slightly every bit it dries, so press information technology in tightly and go out it mounded slightly above the surface of the woods.

Wood filler dries fairly rapidly, only let it prepare for at least two days. Then smooth the patch lightly with fine-grit sandpaper and buff the expanse with No. 0000 steel wool. If surrounding cease is involved, feather the edges and so that the new patch blends in with it. So, if necessary, stain the patch and buff information technology lightly with No. 0000 steel wool. Apply finish to match the rest of the surface, using an artists' brush and feathering the edges. Let the finish dry and and so lightly buff it with No. 0000 steel wool; make clean the area of any residue, and wax and smoothen the surface.

Water putty dries flintstone-difficult, ordinarily harder than the forest being patched. It's best used on blank forest. Water putty can exist toned with oil and water stains, but y'all'll have to experiment to come up with a perfect match. To utilize water putty, mix the powder with h2o to the consistency of putty; so trowel information technology into the break with a putty pocketknife, leaving the patch slightly high. Allow the patch dry completely, and sand and steel-wool the area smooth and level with the surrounding surface. Finish the surface as above, or finish the unabridged article of furniture.

For the most professional patching job, apply shellac sticks to fill cracks and gouges. Shellac sticks leave the least conspicuous patch, and are very effective on finished wood that'south in practiced condition. Shellac sticks are available in several woods-tone colors; use a stick that matches the finish every bit closely as possible. Practice on scrap wood before working on a slice of furniture.

© Publications International, Ltd. Rut the shellac stick over an alcohol lamp or a propane torch, belongings a palette or putty knife betwixt the stick and the flame to keep information technology from dripping.

Carefully clean the scissure or gouge with the tip of a arts and crafts knife. Shellac sticks must exist heated and melted to fill the crack. The all-time heat source for this is an booze lamp or a propane torch turned to a low setting. Exercise not use a friction match to soften the stick; the smoke from the friction match may discolor the shellac. Do non utilize a range burner; liquid shellac could damage either gas or electrical ranges. Hold the stick over the blade of a palette knife or a putty knife to preclude it from dripping.

To utilize a shellac stick, hold it to the heat source higher up the knife, until it has softened to nigh the consistency of glazing compound or putty. Then apace press the softened shellac into the cleft and polish it with the hot knife. Make certain the soft shellac fills the pause completely; it hardens quickly, so you'll have to work fast. Go out the patch slightly high. Then, with the heated putty knife blade, trowel the shellac shine.

Let the patch gear up for ane to 2 hours. When the shellac is hard, plane or sand the surface smoothen and level. The end surrounding the break usually doesn't take to exist retouched, but the surface can be coated with shellac, if desired. Utilise the shellac finish. To make the shellac match a satin-gloss finish, rub the surface smooth with No. 0000 steel wool and linseed oil.

To fill very deep holes, employ wood plastic or water putty to fill the hole almost level. Let the filler dry completely, and then fill up the indentation with a shellac stick.

If a pigsty or split is very large, don't overlook the possibility of filling information technology with a slice of wood cut and trimmed to fit perfectly. If the patching woods can be taken from the piece of furniture in a spot that won't testify, the repair may be nearly incommunicable to detect.

Fit the wood patch into the hole or split; utilize carpenters' glue to bond it to the surrounding wood. Get out the patch slightly high. When the glue is completely dry, sand the plug smoothly level with the surface of the surrounding wood. Then refinish the furniture.

Even if the wooden surface is burned, information technology tin can nevertheless exist repaired. Tips for removing mild scorches and for fixing more serious burns are outlined in the adjacent section.

How to Repair Burns

Burns on wooden furniture can range from scorches to deep char, but the usual problem is cigarette burns. These damages can be removed as long as the problem doesn't go across the surface and extensively affect the wood.

Scorches from cigarettes or cigars are unremarkably the easiest to remove. Buff the scorched area with a fine steel wool pad moistened with mineral spirits until the scorch disappears. Then wipe it clean and wax and polish the surface.

More serious burns require the removal of the charred wood. Shallow burns, when repaired, will always leave a slight indentation in the wood, simply this depression will non exist conspicuous. Deep burn holes can be filled.

Beginning, remove the damaged wood. With the flat precipitous edge of a craft knife, very carefully scrape away the charred wood. For deep burns, use a curved bract. Practise non scratch the burn area. Scrape away the char right to the blank wood, feathering out the edges. Whatsoever burned or scorched spots will bear witness, so all the burn crust must be removed. Work carefully to avoid scratching the wood with the point of the knife.

When the charred forest has been completely removed, lightly sand the edges of the groove or trench to level information technology with the surrounding surface as much as possible. Press lightly into the groove with fine-dust sandpaper, removing but the char from the burned area. Exist careful non to damage the surrounding finish. If you're not sure all the burn has been removed, moisture the sanded area. If water makes the burned area look burned again, you haven't removed all the char.

With deep burns, the groove left after the char is removed will probably exist quite noticeable. Level the groove equally much as possible with fine-dust sandpaper, simply stay close to the edges of the groove. If y'all sand too far out from the fire area, the damaged area will be very visible as a broad saucer-shaped indentation. If the depression isn't too deep, try swelling the wood as detailed in a higher place for dents. If you're left with a deep gouge, the burn area can exist filled with forest plastic or a shellac stick.

Later smoothing out the burn down, refinish the damaged surface area every bit above. Let the new cease dry for one or two days, and so lightly buff the patch with No. 0000 steel wool to blend the edges into the old stop. Finally, wax and polish the unabridged slice of furniture.

Veneer, a thin layer of wood attached with glue to a solid base, is peculiarly vulnerable to impairment. In the adjacent section, we'll testify you how to make diverse repairs to this surface.

How to Repair a Veneer Surface

Because veneer is only a thin layer of wood fastened with glue to a solid base, it is very vulnerable to damage on wooden furniture. On sometime furniture, the glue that holds the veneer is often not h2o-resistant. Prolonged humidity or exposure to water can soften the glue, letting the veneer blister, crack, or peel. Veneer is likewise hands damaged from the surface, and old veneers are often croaky, buckled, or cleaved, with chips or unabridged pieces missing. In this article, we'll talk over bones techniques to repair veneer on your wooden furniture for whatsoever at-dwelling house furniture refinishing or restoration project.

In most cases, as long every bit the veneer layer is basically in good shape, the thinness that makes it harm-decumbent too makes information technology easy to repair. Undamaged veneer can be reglued; chips and bare spots tin be filled with matching veneer. If you're careful to match the grain the repairs will hardly prove. In this section, nosotros'll show y'all how to make repairs to several veneer problems.

Blisters

Small blisters in veneer can usually be flattened with heat.

To protect the surface, set a sheet of wax newspaper and then a canvas of smooth cardboard on the surface, and embrace the cardboard with a clean cloth. Printing the blistered area firmly with a medium-hot fe. If there are several blisters, move the iron slowly and evenly back and forth. Be careful not to touch the exposed surface with the iron.

Check the surface every few minutes or then every bit you work, and stop pressing equally soon every bit the blisters take flattened. Leaving the cardboard in place, weight the repair area solidly for 24 hours. So wax and polish the surface.

Large blisters must ordinarily be slit, considering the veneer has swelled. With a sharp craft pocketknife or single-border razor blade, carefully cut the blister open downwards the center, forth the grain of the wood. Be conscientious non to cut into the base wood. And so cover the surface and apply rut as above, checking every few seconds every bit the mucilage softens; if the glue has deteriorated and does non soften, carefully scrape it out and insert a petty carpenters' glue nether the slit edges of the bubble with the tip of the pocketknife.

Exist careful not to employ likewise much glue. If necessary, wipe off whatsoever excess as the blister flattens. As soon as i edge of the slit chimera overlaps the other, carefully shave off the overlapping edge with a craft knife or razor bract. Oestrus the blister over again; if the edges overlap further, shave the overlapping border again. When the cicatrice is completely flattened, weight the repair area solidly for 24 hours. Then wax and polish the entire surface.

Loose Veneer

Lifted veneer occurs about often at the corners of tabletops, on cabinet and dresser edges, legs, and drawer fronts. If the loose veneer is undamaged, it tin can be reglued.

©Publications International, Ltd. Loose veneer can be reglued. Apply glue to the base wood, press the veneer into identify, and clench it firmly.

Showtime, remove the residual of old glue left on the back of the veneer and on the base forest. With a sharp craft pocketknife or razor bract, carefully scrape out every bit much of the old glue as possible. Don't elevator the veneer any further; if you bend it upwardly, you'll impairment it.

Subsequently scraping out as much onetime glue as you tin, make clean the bonding surfaces with benzene or naphtha to remove any residue; gum left under the loose expanse volition interfere with the new agglutinative. If whatever gum all the same remains, sand the bonding surfaces lightly with fine-grit sandpaper, and then wipe them clean with a soft cloth moistened with mineral spirits. If more than ane veneer layer is loose, clean each layer the same way.

The veneer tin can exist reattached with contact cement, merely you may prefer to employ carpenters' glue considering information technology sets more slowly and allows repositioning. To reglue the veneer, apply contact cement to both bonding surfaces and permit information technology set, as directed by the manufacturer. If necessary, set a small tack or 2 between the layers to proceed them from touching. If you'd adopt to use carpenters' glue, apply a small brush to spread it forth the grain. Then, starting at the solidly attached veneer and working out toward the loose border, smooth the loose veneer advisedly into place.

Contact cement bonds immediately, so make sure the veneer is exactly matched; if you're using carpenters' mucilage, press from the heart out to force out whatever backlog, and wipe the excess off immediately. If more than one veneer layer is loose, work from the bottom up to reglue each layer.

Reglued veneer, whatever agglutinative is used, should exist clamped or weighted. To protect the surface, embrace information technology with a sheet of wax paper; brand certain all backlog glue is removed. Set a buffer block of flake woods over the newly glued area, and use another block or a soft cloth to protect the reverse edge or side of the surface. Clamp the glued and protected surface firmly with C-clamps or hand screws, for one to 2 days. Then remove the clamps and the buffers, and wax and polish the unabridged surface.

Cracked or Cleaved Veneer

If the veneer is lifted and cracked, but not broken completely through, it can be reglued. Large areas may be easier to repair if you lot break the veneer off along the cracks. Broken veneer can be reglued, but you must exist very careful not to damage the edges of the break. Do not trim ragged edges; an irregular mend line will not be as visible as a perfectly directly line.

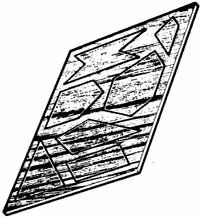

© Publications International, Ltd. To mend veneer, cut a patch in an irregular shape; any of these shapes will be less visible than a square.

Before applying glue to the veneer, make clean the bonding surfaces carefully, as above. Fit the broken edges carefully together to make sure they lucifer perfectly. And so utilize contact cement to both surfaces, or spread carpenters' glue on the base wood. Ready the broken veneer carefully into place, matching the edges exactly, and press firmly to knit the broken edges together. Clamp the mended area. Refinishing may be necessary when the mend is complete; if and then, utilize a non-wash-abroad paint and varnish remover, and treat the veneered surface very gently.

Chipped or Missing Veneer

Replacing veneer is easy, but finding a new piece to replace information technology may not be. If the piece of furniture is not valuable, you may be able to take the patch from a part of it that won't show. The patch area must be along an edge, and then that yous tin lift the veneer with a craft pocketknife or a strong-bladed putty pocketknife.

In nearly cases, patch veneer should non be taken from the same piece of piece of furniture; y'all'll have to purchase matching veneer to make the repair. If just a small piece is missing, you lot may exist able to make full in the hole with veneer edging tape, sold at many abode centers and lumberyards. Or, if you lot accept access to junk furniture, you lot may be able to salvage a like veneer from another piece of furniture. For larger patches, or if yous tin can't find a scrap piece of matching veneer, buy a sheet of matching veneer from a specialized forest supplier. National veneer suppliers tin can exist found by searching the Internet.

To fit a chip or very modest patch, prepare a sheet of bail paper over the damaged veneer. Rub a very soft, dull lead pencil gently over the paper; the edges of the damaged expanse volition be exactly marked on the paper. Employ this pattern as a template to cut the veneer patch. Tape the pattern to the patching forest, matching the grain of the new veneer to the grain of the damaged expanse. Cutting the path firmly and carefully with a sharp craft knife; information technology'southward better to make it too big than too small.

© Publications International, Ltd. Before gluing the patch in, examination it for fit; it should fit exactly, flush with the surrounding surface, with no gaps.

To make a larger patch, record the patching veneer firmly over the damaged area with masking tape, with the grain and pattern of the patch matching the grain and pattern of the damaged veneer. Make sure the patch is flat confronting the surface, and deeply held in place.

Cut the patch in an irregular shape, equally illustrated, or in a gunkhole or shield shape; these shapes will exist less visible than a foursquare or rectangular Patch Would be. Cut the patch advisedly with a craft pocketknife, scoring through the patching veneer and through the damaged veneer layer below it.

Untape the patching sail and pop out the patch. With the

tip of the craft pocketknife, remove the cutting-out patch of damaged veneer; if necessary, score it and remove information technology in pieces.

Be very careful non to impairment the edges of the patch. Exist very careful non to damage the edges of the patch surface area. Remove simply the top veneer laver; do not cut into the base wood. Remove whatever quondam glue and clean the base of operations woods as above.

Test the fit of the patch in the hole. It should fit exactly, flush with the surrounding surface, with no gaps or overlaps. If the patch is too big or besides thick, practice not force it in. Carefully sand the edges or the back with fine-girt sandpaper to fit it to the hole.

Glue the fitted patch into place with contact cement or carpenters' glue, as in a higher place, and clamp or weight it solidly. Allow the repair dry for 1 to two days; then very lightly sand the patch and the surrounding veneer. Re-end the damaged surface area or, if necessary, the entire surface or piece of piece of furniture.

In the final department, we'll show you lot how to repair a fundamental furniture-surface accessory: the hardware.

How to Repair Furniture Hardware

The hardware on old furniture -- drawer pulls, handles, hinges, locks, protective corners, and decorative bands and escutcheons -- often shows signs of long, hard use. Sometimes hardware is missing; sometimes it'due south loose, broken, or bent. Loose hardware can exist repaired; missing or damaged pieces should be replaced. Replacement is also the solution if you don't similar the existing hardware. In this article, we'll talk over some techniques to quickly replace or repair worn hardware on your wooden furniture so they work again.

Many pieces of furniture are made with very common types of hardware; matching these basic designs is fairly simple. If the hardware is more distinctive or unusual, information technology may be easier to supplant all the hardware than to find a matching slice; make sure the new hardware'southward bases are at least as large as the old. Merely if the piece of piece of furniture is very valuable or an antique, or if the hardware is very bonny, the old hardware should not be removed. In this example, missing parts should be replaced with matching or like hardware; a slight difference in design unremarkably doesn't look bad.

Hardware stores, domicile centers, and similar stores offer a fair selection of furniture hardware; specialty hardware outlets and craft suppliers are commonly better sources. Search the Internet for hardware vendors. Let's become started by reviewing how to handle a mutual hardware problem -- loose drawer pulls and handles.

Drawer Pulls and Handles

To tighten a loosely fastened drawer pull, remove the pull and replace the screw with a longer one. If the screw is part of the pull, y'all'll have to make the hole in the woods smaller. When the hole is only slightly enlarged, you can tighten the pull past using a hollow fiber plug with the screw. For metal pulls, fit a slice of solid-cadre solder into the hole and then supersede the screw.

When the hole is much too big, insert woods toothpicks or thin shavings of wood, with glue applied on the outside, into the hole. Permit the gum dry out and carefully trim them flush with the wood surface. Then dip the pull's screw into glue, replace the pull, and tighten the screw firmly. For a more substantial repair, overstate the hole, glue a piece of dowel into it, and drill a new screw pigsty.

Hinges

Hinges that don't work properly usually take bent swivel pins; in this instance, replace the hinges. If the hinges are loose, try using slightly longer screws to attach them. When the screw holes are very much enlarged, accommodate them past ane of the methods detailed above. If the hinge leaves are damaged and the hinges cannot be replaced, mucilage the hinges into position with epoxy or a rubber- or silicone-base adhesive.

Locks

Locks on onetime pieces are oft damaged, and keys are ofttimes missing. If the piece of furniture is an antique, or the lock is very unusual, have it repaired by a professional. Otherwise, remove the damaged article of furniture lock and have it to a locksmith; order a matching or similar lock to replace it.

Loose Metallic Bands and Escutcheons

Former bands and escutcheons often accept an attractive design and patina; don't replace them unless they're badly damaged. To secure a loose ring or escutcheon, squeeze adhesive caulking chemical compound under the metal, and press it downward to bond information technology to the wood. If this doesn't work, fasten the ring or escutcheon with tiny metal screws, of the same metal every bit the hardware. You must friction match the metals -- brass to contumely, copper to copper, steel to steel, or whatever. If you don't friction match the screws to the metal plate, the metal will corrode. Utilize several screws, placing them to class a pattern; drill airplane pilot holes before inserting them.

Coverup Hardware

If sometime hardware holes are impossible to repair, or if you want to modify the look of a piece entirely, the surface tin be covered with new wood or metal escutcheon plates. Escutcheons are used peculiarly nether drawer pulls or handles; many handles are made with escutcheon-type backers. Adhere the escutcheons with adhesive or screws, matched metal to metal. If you're using escutcheon-type handles, no other handling is necessary. If you lot're using an escutcheon under other hardware, drill new mounting holes equally required. Continue your design simple, and try to match the mode of the piece.

So whether it's the hardware, the veneer, or a burn, at that place probably is a solution. The end result is a furniture surface that stands up to the everyday chirapsia it inevitably takes.

©Publications International, Ltd.

Originally Published: May ten, 2006

Woods Piece of furniture Repair FAQs

Practise vinegar and olive oil fix the scratches on wood furniture?

Yes. Olive oil and vinegar have the necessary ingredients needed to prepare scratches in on wood piece of furniture. Mix three parts of oil to one function of vinegar. Pour only a piddling onto the scratch and permit it soak for at least 24 hours before wiping information technology off. Repeat until the scratch is gone.

How much does sofa repair cost?

This really depends on the impairment done to the sofa. In well-nigh cases, article of furniture repair costs anywhere from $100 to $300, or near $150 on average. Information technology tin can be much more if you lot need to reupholster the burrow.

How can yous repair dents in wood?

Put a few drops of water in the dent. Adjacent cover the area with a damp cloth. Use an iron at max setting and employ information technology onto the damp cloth. This should set the paring by forcing the wood fibers back into their original position.

How practice you fix tarnished wood?

One common home remedy is to mix canola oil (or olive oil) with vinegar. Use 3 parts oil to i part vinegar and apply some of the mixture to a soft textile and rub the furniture. This will make your wood pieces as adept equally the day you first bought them. The combination of oil and vinegar can likewise repair scuffs with ease.

How To Fix A Varnish Spot On Furniture,

Source: https://home.howstuffworks.com/home-improvement/home-diy/projects/how-to-repair-wooden-furniture-surfaces.htm

Posted by: petersonwhichoune.blogspot.com

0 Response to "How To Fix A Varnish Spot On Furniture"

Post a Comment